It was so good to be back at the shop. The Volkert was looking beautiful, with the pinblock, plate, and strings newly installed. Bernard's property was covered in vivid greens, one of his hens was brooding, and the sun was out. After some fiddle and banjo music, Bernard played a recording called Betty Boop's Musical Cabaret. I later learned that Betty Boop was originally created as a caricature of the singer Helen Kane, but her voice was mostly done by a woman by Mae Questel. I wish I could find an album of Mae Questel, but it's not easy.

Much of the day was used screwing the shanks/flanges to the action rails. You might recall the grasshopper incident from when I first lacquered these screws on 11 Nov 11. Pictured below is a flange with a piece of tape on it, connected to the longer shank which will later attach to the hammers. The action rails are the frame holding everything in place, and can be viewed separately in the last picture of 177448/3 (18 Nov 11).

My task was to order the shanks/flanges according to joint stiffness, number them, screw them down onto a fitted piece of sandpaper on the action rails, and correct any obvious incidences of "travelling." A shank is said to "travel" when it fails to remain parallel to its neighboring shanks when lifted. The solution is to put a thin piece of masking tape onto the bottom of its flange to seat it more squarely onto the action rails. Look at how thin the tape is!

Friday, 30 Mar 12

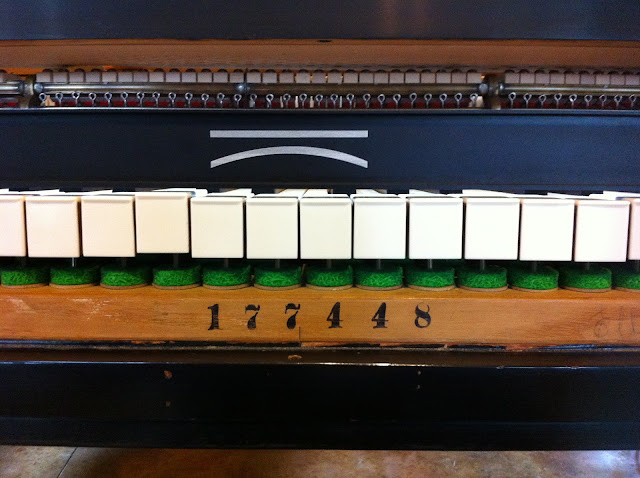

Jack was back! It was nice to chat with him during the morning and have lunch with Osious in the afternoon. I started the day by screwing the let-off buttons into the action rail. My next task was to custom cut the key end felts with the guillotine and glue them to the keys. As I always say, any day spent with hide glue is a good day.

I sat in one spot with some screwdrivers and enjoyed the company of the Friday crew: Bernard, Osious, and Jack. First I screwed the wippens to the action rails, which didn't take too long. Then I tried to screw and adjust the capstans to the keys, and that took the rest of the day. Bernard explained that a capstan in nautical terms is a large rotating device that strong men pushed in order to raise an anchor. Because they don't do this without musical accompaniment, Bernard demonstrated a "sea chanty," which was about how he once loved a young French lass that turned out to be ugly and crazy, "Johnny O." It was really great. Bernard also showed us seven chicks that had hatched, and they were adorable.

A capstan in piano terms is a screw that connects the back of the key with the wippen, which touches the hammer knuckle that hangs down from the hammer shank, which sends the hammers flying into the strings. That means that before I went home, I was able to use a key to produce a sound on The Volkert for the first time since August.

Jack brought everybody a jar of fresh honey that his bees made from peach blossoms. It's amazing! He has a very nice and informative beekeeping blog, if you'd ever like to know more bees. Celeste was also in the shop, and guided me through several projects.

Most of my tasks involved a preliminary straightening of the keys in various ways. By moving the balance rail pins, I tried to "square" the keys so they wouldn't angle much to the right or the left. Next, I altered the front rail pins to "space" the keys so that the gaps in between keys are similar. Finally, I began to "level" them with the key-leveling bar shown below. I measured how much taller the fronts of each key need to be in order to add the correct types of punchings on the balance rail pins. I think I lost track and messed up somewhere in the highest octave.

The biggest job of the day was installing the backchecks to the end of the keys. Because the backchecks were too long, I clipped them with a heavy set of pincers and shaped the ends with a belt sander, which was a little bit scary. Then I drilled out the holes at the end of the keys and forced the backchecks down with a drill press. Afterwards, I straightened them in various ways with fancy backcheck tools.

Before all of that, I adjusted the strings under the capo d'astro bar and aligned the hammers a little bit. I also leveled the keys while the hammer shanks were still resting on the wippens, which doesn't do anything right. Piano technicians reading this think I'm an idiot. Everybody else can call me a beginner.

I made a third pass at leveling the keys. Because I accidentally made several keys too high last week, it was necessary to remove punchings to some keys and add punchings to others. The punchings belong under the keys on the balance rail pins they are resting upon shown below.

For treble keys 75 to 86, my white keys (naturals) needed no extra punchings, whereas many of the black keys (sharps) did. The chalk marks indicate that I need to remove punchings, but since I didn't know which ones were underneath, I guessed at .010" or .020." The hope was to take off the right amount or a little too much, which will be easier to fix during the next round of leveling. For the sharps, the green punchings are .005," and the pink are .007." The arrow on top of key 85 indicates that the balance rail pin needs to move left to square the key, and the bigger arrows below indicate that the front rail pins need to move left for better spacing.

But the most exciting part of the day was that I found out I can remove an action all by myself! I'm not good at it, and it hurts my palms, but it's still a victory.

END PART VII

No comments:

Post a Comment