INTRO

GEORGE'S BIRTHDAY PRESENT 2023

We can all agree that soap is a boring, generic gift.

But George and I are now boring, generic people, and that means that no new-fangled contrivance pedaled by any "bang-beat, bell-ringin', big-haul, great-go, neck-or-nothing, rip-roarin', every-time-a-bull's-eye salesman" tops a bar of chocolate, a package of smoked salmon, a sturdy pair of socks, or a lovely bar of soap. But truthfully, it's even worse than that. Whole Foods carries all of those things, and I only walk in there to ogle their pumpkins (when they're in season) or spend a personal moment with their soap stand, under the assumption that a couple minutes of reading labels like "turmeric goat milk" or "rosemary mint" or "desert sage" three times a year qualifies as "adequate self care."

Every year for George's birthday, I spend a small fortune on a year's supply of bar soap, with at least half the haul being pine tar soap. And not just any pine tar soap will do. Dr. Squatch isn't as pine-tarry as Grandpa's, so it's not good enough. And no matter how many other interesting soaps I find, George goes through them as quickly as possible until he is left with his favorite - Grandpa's pine tar. It's both adorable and annoying.

This year, instead of spending a small fortune on pine tar soap, he and I are becoming soap makers just by my writing of this post. And in place of spending a small fortune on a year's supply of bar soap, I will be spending a smaller fortune on half a year's supply of bar soap in addition to an unreasonably large fortune on soap making supplies. If you know me, you will agree that this is the most predictable thing I could possibly be doing. I have 3 weeks to complete this painfully inevitable project. I will abandon George to do this, and he will be sad because he misses me, and then he will love his birthday present, and we will decide that the sadness was worth it. This is a tradition in our marriage. He is sad now, and he will be sad one year from now, and again the year after that. So much abandoning and so much sadness commences the moment we start thinking about harvests and blessings.

And so it begins.

CHAPTER 1: WHAT IS SOAP?

SODIUM HYDROXIDE OR POTASSIUM HYDROXIDE & TRIGLICERIDES

What is soap?

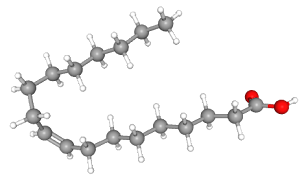

Soap is a lathering substance that's created when fats are adequately mixed with a strong base. Lest we be too pleased with ourselves for understanding that, soap is "the salt of fatty acid." On the molecular level, it has little water-loving (hydrophilic) heads and long skinny water-fearing (hydrophobic) tails. I totally hate chemistry, so I'm done writing about this now. It's time for a picture.

The one below hints at chemical polarity, which I shall never mention, probably ever again, in all my days. The masses of soap molecules surrounding the things we want to get rid of, like dirt or oil or bacteria or viruses, along with those things, are called micelles.

What is lye?

Lye is a base that's soluble in water, which makes it an alkali, and it is very strong. The word "lye" most commonly refers to sodium hydroxide (NaOH), but sometimes means potassium hydroxide (KOH). NaOH is also called "caustic soda," and KOH is also called "potash." I like the word "potash" better. When adequately mixed with fat, NaOH creates bar soap, and KOH creates liquid soap.

What is fat?

The fats we're talking about are triglycerides, which are molecules comprising three fatty acid chains attached to a glycerol. Glycerol is (C3H8O3), and each fatty acid is a carboxylic acid (CO2H) with a hydrocarbon chain (more C's and H's). Whatever that means.

What is saponification?

Saponification is the chemical reaction that allows lye-water (an aqueous NaOH solution) and tryglicerides to form soap. When adequately agitated together, the glycerol from the triglycerides break off, and the sodium or potassium from the lye bonds with the fatty acids to make soap. Now "salt of fatty acid" isn't quite as weird as it was a minute ago, is it? But it's still pretty weird. Hang tight while I take leave of this authorship to create a customized soap stamp that reads "salts of fatty acids." Or better yet, "salts of fatty acids with glycerol superfatted." (We'll get to the "superfatted" thing later; I really cannot be bothered until this task is completed.)

Okay, we can all relax. It's ordered.

I got tired of chemistry again. Here are two excellent photos I took from chemistrylearner.

Who cares what the hell the variable "R" means in chemistry? I guess it's some generalized chain of something, but this one time, it meant C17H35, or as we'll see in chapter 3, CH3(CH2)16, and I think that's enough of that. But remember, kids, the fatty acids in triglycerides don't have to match each other just because they did in this one example.

CHAPTER 2: HOW DO YOU MAKE SOAP?

HOT & COLD PROCESS SOAP MAKING

From what I can tell, there are four ways to make soap, but only two that matter. I've been an imaginary soapmaker for a matter of days at this point, so I'm pretty sure I'm qualified to say that. The two unimportant ones are called "melt and pour" and "milling" or "rebatching," and due to my strict policies prohibiting the creation of boring chapters, we shall leave that to the chemical polarity people.Both cold and hot process soaps require the preparation of an aqueous NaOH solution, the melting together of fats, and the combining of these two things. Both of these steps - dissolving NaOH in water and introducing that solution to fats - generate heat. When sufficiently agitated, most often with an immersion blender, aqueous NaOH and fats start to emulsify and become thick; in the soap making world, this moment is described as "reaching trace."

Cold process soap making typically ranges from 40 to 55°C, and hot process typically ranges from 60 to 80°C. Let's just take a moment to discuss F vs. C. I don't have a problem with F, but I do have a problem with ounces and fluid ounces. My units of weight will be grams and my units of volume will be cubic centimeters, and it just seems that a person making that choice ought to stick with Celsius.

F = C(9/5) + 32.

Freezing water is 0°C and 32°F.

C and F are equal only at -40°.

In cold process soap making, reaching trace is like finishing your cookie dough. Now is the time to add your chocolate chips, dried cherries, and pecans (fragrances, colors, and exfoliants). From here, saponification begins to generate heat. If the soap heats up to 70-80°C, the colors may intensify and the soap may take on a shiny or glossy appearance. This is called the "gel phase."

If the gel phase is desired, trace-accelerating ingredients such as sugar or alcohol may be used, higher soaping temperatures may be chosen, molds may be heated with an electric blanket, and molds may even be insulated with blankets, coolers, or warm ovens with the heat turned off. If the gel phase is not desired, the soap can be mixed at lower temperatures, remain uninsulated, and left to its own devices in a cool environment. Individual molds or longer thin molds are better for avoiding gel phase. If gel phase only occurs in the center of the soap, it's called a partial gel. It's a little bit ugly.

For cold process, saponification will not be complete for one to two more days, during which time the pH level should drop from about 14 to 9-10. Before this happens, all dirty dishes are still caustic. Once the soap is ready to unmold, it may need more time before being cut into bars or stamping. Bars of soap should cure from about 4 to 6 weeks, during which time they will lose about 10% of their weight through water evaporation.

In hot process soap making, ingredients are brought to trace in a slow cooker and heated to about 60-80°C. The soap, therefore, always goes through the gel phase. Hot process soap is cooked until completely saponified, and this process can take a few hours. The batter will be very lumpy once it's ready to be poured into the mold, and it is at this point that hot process soap is ready for add-ins. Although this process initially requires more time, the bars are ready to un-mold much sooner. Also, clean up is much easier because everything is actual soap.

Most people seem to gravitate towards cold process soap making. Because the soap is poured before it has completed saponification, it's not lumpy, which makes it a better process for decorative techniques such as layering and swirling. Generally speaking, cold process soaps are considered more polished while hot process soaps are considered more rustic and old fashioned.

The main advantage to hot process soap in my opinion concerns that "superfat" thing I mentioned earlier. We always want to make sure we're not making lye bars, so we use extra fat to overwhelm the lye. In cold process, the extra fat is chosen by the chemistry - not by us. In hot process, superfat can be added after the saponification is complete, which means that the fats floating around to moisturize our skin are the fats we're choosing for that purpose. Hot process soap also eliminates two purely aesthetic issues - soda ash and glycerin rivers - that can happen in cold process soap. Soda ash is the result of unsaponified lye reacting with the CO2 in the air, and can be prevented by spraying the surface of the soap with isopropyl alcohol. Glycerin rivers may form when cold process soap gets overheated with too much water. A less common problem that is also resolved by hot processing is the formation of "stearic spots," which happens when saturated fats start cooling and solidifying before fully saponifying.

When soaping too hot, the soap can start to harden on the outside and expand outwards from the inside, causing something unsightly that looks like a bit of an explosion. That's called volcanoing. (If you ever see your soap starting to crack, cool it down immediately).

In cold process, it's possible for the lye water to be cold enough to harden fats with higher melting points, and the mixture begins to look thicker for this reason. This is called "false trace." Nobody wants that any more than they want some lye water, random fats, a dirty kitchen, and a broken heart, so it's a good idea to know the melting points of your fats. Most fats (not waxes) will still be fluid around 50°C, so that's a good temperature to aim for with cold process. But also, false trace is gross and lumpy, so don't be a sucker. Just keep mixing and the saponification will generate the heat required to unlumpify the soap batter. Hope that helps.

Scents, colors, and exfoliants behave differently with the two processes. With cold process, these ingredients will go through an extreme pH change after they're out of your hands, and some ingredients don't handle that very well. With hot process, they are exposed to more heat, which makes cold process a better choice when using ingredients that easily scorch and discolor, such as milk, vegetable juices, and purées. Both types of soap need time to cure, during which time excess water will evaporate and their structures will transform. More on that in chapter 10.

CHAPTER 3: FAT PROPERTIES

FATTY ACIDS & MEASURING HARDNESS

Each fat has a variety of fatty acids.

There are only eight primary fatty acids in soap making, so there are only eight primary soap molecules to discuss. Because each of them has different properties regarding firmness, lathering, cleansing, and gentleness, a good soap recipe uses a well-calculated balance.

Fats in which all the chemical bonds in the fatty acid chains are single bonds are called "saturated fats." They're easy on the eyes and fairly straight and bad for your health when consumed. When there's at least one "double bond" in the chain, the fatty acid is considered "unsaturated." Within the world of unsaturated fats, chains with one double bond are called "monounsaturated," and chains with two or more double bonds are called "polyunsaturated," which can also be further subdivided into "doubly unsaturated" or "triunsaturated."

Of our eight soaps, the first four are made with saturated fats of increasing lengths.

The next two are made from monounsaturated fatty acids.

The seventh is made from a doubly unsaturated fatty acid, and the eighth, a triunsaturated fatty acid.

Saturated fats accelerate trace and saponify more quickly than unsaturated fats. The shorter carbon chains in lauric and myristic acids make them more soluble in water, which means they're not as long lasting. They make the most cleansing of the soaps, to the point that they can be drying. They also make the hardest bars of soaps, to the point that they can be brittle.

The longer carbon chains in palmitic and stearic acids produce a more stable, long-lasting lather. These fatty acids are still very cleansing and create hard bars of soap, and their lathers have smaller bubbles.

Let's take a moment to complain about ricinoleic acid. That shit has a hydroxyl bond, and that just makes me mad - so mad that I highlighted it in bright screaming yellow. I was not under the impression that hydroxyl bonds could just waltz into fatty acid chains at their leisure because nobody told me that, and this is why I hate chemistry. I only like art and math. In art, you put as many hydroxyl bonds as you are so moved, usually to best convey your message, and sometimes that's zero hydroxyl bonds, and sometimes it's one million. And in math, you put the correct amount of hydroxyl bonds in there, whatever that may be. Let's hurry up and get on with the other unsaturated fats so we can get out of this garbage and onto the equations, where the world will make sense again. So as I was saying, ricinoleic fatty acid makes up about 90% of castor oil and pretty much nothing else. It accelerates trace and saponification, and assists with lather formation. If used in larger amounts, like any more than 15% of the total fats by weight, the soap will become soft and sticky. Serves it right.

The properties of unsaturated fat soaps are opposite of the saturated fat soaps. They decelerate trace and saponify more slowly. They hinder lather and have milder, gentler cleansing properties, so they're better for sensitive skin. Oleic fatty acids make up the bulk of unsaturated fats in soap making; linoleic and linolenic are often used in smaller amounts and associated with luxury oils. Soaps with too many oleic fatty acids can be gooey, especially in humid weather. Because they're slow to trace, they're great to work with for layering and swirling.

It's typical for linolenic fatty acids to make up only 0-1% of the total fats by weight, so linoleic and linolenic are often computed together. These fats have a relatively short shelf life, and it is recommended that their combined weight be 15% or less. Any more puts the soap at risk for dreaded orange spots, or "DOS."

Very generally speaking, these are some guidelines for fatty acids in soap making.

Even more generally, these are some guidelines for oils.

Harder than saturated fats are waxes. They're made of fatty acids and other stuff, but come with the price of higher melting points. They're a little better suited for hot process soaping, but can be used if handled carefully with cold process as well. In small quantities, meaning 1-5% of total fats by weight, waxes can increase hardness and lather stability. More than that can lead to poor lathering :(

In ranking the hardness of soaps, there's one more term that commercial soap makers use, but it's usually ignored in home soaping, because it doesn't tell the whole truth. The "iodine value" of an oil is the amount of iodine, measured in grams, that is consumed by 100 grams of that oil. The cool thing about this is that you can get an iodine number for not just any oil, but a blend of oils. Unsaturated oils will consume more iodine solution, and will therefore have higher iodine values. In other words, blends with higher iodine values have a higher percentage of unsaturated fats, and blends with lower iodine values have a higher percentage of saturated fats.

Each oil or oil blend also has a saponification value, which is the number of milligrams of NaOH needed to saponify one gram of that oil or oil blend. Saponification values measure chain length or molecular weight. Oils with lots of short chains like our little friend lauric acid can cram more chains into a gram, so they have higher saponification values. In other words, blends with higher saponification values have a higher percentage of saturated fats, and blends with lower saponification values have a higher percentage of unsaturated fats.

If you take the saponification value of an oil blend and subtract its iodine value, you get the iodine number saponification, or "INS." So let's imagine finding the INS of something extreme. Glycerol trilaurate would be that - a triglyceride with three lauric acid chains. Its saponification value would be as high as possible. It's iodine value would be as low as possible. And the difference would therefore be as much as possible, or "big." "Big" therefore means drying and crumbly, while "small" means gooey and not as cleansing. "Big" happens to be about 260 and "small" happens to be about 45.

But the point I've been trying to get to was that the INS was developed in the early 1900's as a way to check oil blends for mass production, and the goal was about 160. And to reiterate, home soapers do not care. It's nice to know, that's all.

CHAPTER 4: OUT OF THIS GARBAGE AND ONTO EQUATIONS

HOW MUCH LYE

Even though iodine values and INS are kind of a waste of time because nobody cares about them, saponification values matter tremendously. Without them, we couldn't write our own recipes. But fear not!

Now that we know all about our fatty acids, the first step is to choose our fats and the total weight of our fats; this is what's used to scale our recipe. We'll talk about how to work that out shortly, but for the purposes of this discussion, let's assume we'd always like to work with 1,000 grams of fat. When choosing our fats, here are some articles by companies trying to sell them to us, but there's no reason to read any of that posthaste because Costco sells two popular soaping fats: coconut oil and olive oil.

The second step is to assign percentages to those fats (and therefore the weights of each).

Here are some examples:

The third step is to look up saponification values for each fat.

We plan to use NaOH, so we will look up NaOH saponification values.

We can calculate the amount of NaOH needed for these recipes with just six NaOH saponification values:

The fourth step is to multiply the saponification values by the weight of each oil and add them together to find the total NaOH needed for each recipe.

So that's an approximation of how much NaOH we need. But I already mentioned that we never want to leave unsaponified lye in our soap, because it's... caustic. On the other hand, superfatting at too high a level decreases both lather and cleanliness. A "5% superfat" is fairly standard, and it simply means to multiply our NaOH by 95% or .95. Superfat, therefore, is synonymous with the term, "lye discount." Typically, superfatting levels are 2-8%, so NaOH is often multiplied by something in the range of .92-.98.

And now that we know what's going on, it's a good idea to use lye calculators, which store all the saponification values for you. The biggest advantage is less data entry, which means fewer manual mistakes, but lye calculators also have the potential to store more decimal places so there's less rounding. Two lye calculators I like are Lye Calc and Soap Calc.

CHAPTER 5: OUT OF THIS GARBAGE AND ONTO EQUATIONS

HOW MUCH WATER

Calculating the water is a bit faster.

NaOH requires 1 part water by weight in order to dissolve, and soap may have trouble forming when the water weight exceeds three parts. Let's call the H2O/NaOH ratio, which always ranges from 1/1 to 3/1, R. Popular choices for R are 1.5 or 2.

Thinking in ratios is sometimes translated to "lye concentration," and it's a percentage.

The term "lye concentration" always refers to lye and water; never lye and fats.

So lye concentration % always ranges from 25-50%.

While it is frowned upon in the soaping communities, some people really do calculate water as a percentage of fats instead of lye, and this number is not called "lye concentration" but has the terrible name of "as % of oils" instead. It is important to understand that only bad people do this.

Soap calculators default to the value of 38 "as % of oils," which is on the high side.

Just to make fun of these people, let's find the R values in our four recipes with 380g H2O.

To recap, "lye concentration %" makes sense, "as % of oils" is subpar, and the two can easily be confused.

To nobody's astonishment, I prefer using R.

I'll calculate the weight of water in our recipes when R = 1.5, 2, and 2.5.

Back to writing our own recipes - first we pick our own reasonable default. Soap made with less water can be unmolded sooner; it also loses water at a faster initial rate while curing. We can go with R = 2 (a lye concentration of 33%) or something else; it doesn't matter. Whatever our default is, there are some reasons to deviate from it.

People are very divided on whether more water accelerates or decelerates trace. We all know I hate science, so I'm not about to do a bunch of experiments and then spend all my time on a write up about how my results are either inconclusive, solid before taking experimental error into account, or just completely solid but meaningless because I didn't do the experiment one thousand times in one thousand places when I could just be writing simple equations like a normal person. But I'd wager the key lies in temperature. So I found this graph, which was published on page 3 of the Liquid Caustic Soda Dilution document published by Solvay Chemicals.

Reasons for lower temperature/decelerated trace:

Reasons for higher temperature/accelerated trace:

One approach used by many soap makers is to master-batch a large amount of aqueous NaOH with an R value of 1 and store it. Then when it comes time to soap, the extra water required by the recipe's R value can be added to the room temperature solution. (This extra water could also be obtained by adding water-containing ingredients such as juices or purées). We know from our chart that this additional water will generate heat, but the overall solution would still be cooler than one freshly made. This can save time when using additives that are certain to increase temperature like sugars or alcohols. Or pine tar.

CHAPTER 6: OUT OF THIS GARBAGE AND ONTO EQUATIONS

HOW MUCH FAT

Once we determine the total weight of our fats, we choose our fat percentages, calculate our lye from that, and then calculate our water from the lye. But how do we know what the total weight of our fats should be in the first place? All we have are our molds. And molds measure volume, not weight.

Luckily for us, the density of soap batter is similar to the density of water because fat is a little bigger and lighter than water, but not by much, and lye is much smaller and heavier than water, but we only use a little. In numbers, the story goes like this:

We can use the formula "density = mass/volume" to help compare weight and volume.

Let's take a look at our recipes again.

Choosing R = 2, we'll calculate their weights.

Now we'll approximate their volumes.

Now we'll calculate the ratios between the weights and volumes.

So that's what I was saying - the density of soap batter is a lot like the only substance we understand - water. Looking at the weights of our recipes, it appears that if our molds held about 1,450g of water, we would have been happy to have started with 1,000 grams of fats. And what that means is that in order to estimate our total fat weight, we need to know the volume of our molds, and then multiply it by 1,000/1,450, which is about .7.

You may have noticed that I rounded up for this estimate. Because I want us to have nice full bars, I did not want us in the habit of underestimating our soap batter. I have therefore purchased one soap mold with individual cavities in the event that we do make a little too much.

So the process is this:

CHAPTER 7: A LITTLE MORE GARBAGE:

C3H5NaO3 & NaCl, TiO2 & ZnO, C6H8O7, & C6H5Na3O7

Whenever the soaping community wants "a little bit" of something, they like to say "one teaspoon per pound of oils" or "1 teaspoon PPO." I don't love it because I prefer grams and weight percentages, and teaspoons of different substances weigh very different amounts. The density of sugar is 1.587g/cm3, the density of salt is 2.17g/cm3, the density of mica powders is 2.76 g/cm3, and the density of TiO2, which we'll get to shortly, is 4.26g/cm3. There are 4.928922 cm3 per teaspoon, which means that if we measured with absolutely no air between granules,

But of course, teaspoons are not packed this densely in real life. Sugar is considered 4g a teaspoon, salt 7, mica 5, and TiO2 7. The good news is that nobody seems to care about precision when it comes to these little additions, because everything seems to be "a teaspoon PPO." Or even more sloppily, "one teaspoon to one tablespoon PPO." That sounds to me like "It doesn't matter, but a little bit. Some number of some of the little spoons you find in your drawer."

And if nobody else is caring, then neither should we, and we can just make our own conversion.

Let's say that a teaspoon of anything is 5g, always. Then "tPPO" would be 5/454, which is about 1.1%. That's easy. Then 2tPPO would be about 2.2% and TPPO would be about 3.3%. We can still measure with little spoons, but it's nice to have a very rough weight guide in our back pocket.

Sodium Lactate, the salt of lactic acid (C3H5NaO3), and table salt, Sodium Chloride, (NaCl) are used to accelerate the initial hardening of soaps, which makes unmolding easier, particularly for soaps high in unsaturated fatty acids. Unsurprisingly, it is used at tPPO.

The more salt that's used, the more hard, opaque, and brittle the soap will become, and the less it will lather. Some people make "salt soaps," which use a huge percent of saturated fatty acids in the fat blend to boost lather, and 50-100% of the total fat weight in salt. These soaps must be poured into individual molds because they're too hard to cut. Soaps that are made with significantly less salt than that - perhaps up to about 25% of the far weight in salt - are called brine soaps. Brine soaps were originally made with seawater, which is only 3.5% salt. For cold process soaping, there seems to be no advantage to using C3H5NaO3 over NaCl, but C3H5NaO3 can help keep hot process soaps smoother at 3-5% of the fat weight.

Titanium Dioxide (TiO2) and Zinc Oxide (ZnO) are colorants. They're both white powders that are not water soluble unless formulated to be, and they absorb UV rays. TiO2 is more often used in soaping. As a colorant, how much you want is dependent on the look you're going for, but typically, they're used at tPPO. In practice, one teaspoon of TiO2 is dissolved into one tablespoon of oil, and this mixture can be added in smaller amounts to soap batter at trace.

Sometimes, this TiO2 solution is master-batched, meaning that a 1:3 TiO2 to oil mixture is pre-blended and kept in a bottle with stainless steel bearings inside, like a protein shake bottle. There are a couple of advantages to this; TiO2 is kind of gloopy, so having it pre-blended makes dispersion easier. Also, it's nice to use exactly what you need instead of guessing how much to make.

Mica powders, which are vibrant oil-based colorants, and activated charcoal are used the same way. Powdered clays are also used very similarly, but because they can absorb so much moisture, they are often dissolved into one tablespoon of water instead of oil.

Chelators are chemicals that can trap and hang onto metal ions, which are found in some unrefined soaping oils or hard water. By putting chelators into soap, the metal can no longer cause rancidity or soap scum. Additionally, soap made with chelators will lather better in hard water.

When an acid and a base are combined, a salt is created. Citric Acid (C6H8O7) and Ethylenediaminetetraacetic Acid, also called EDTA (C10H16N2O8) are the acids typically used in soap making, but the most common of these is Citric Acid. Citric Acid (C6H8O7) consumes 3 Lye (NaOH) and produces Sodium Citrate (C6H5Na3O) and 3 Water (H2O). And Sodium Citrate is a chelator! While it's very nice to have a chelator in our midst, we cannot lose our minds rejoicing and forget that some of our NaOH was consumed! For every gram of C6H8O7 in our recipe, we must include an additional .624 grams of NaOH to make up for it. It is recommended to use 1-2% of the oil weight in C6H8O7.

Lemon juice is 4.87% C6H8O7, and lime juice is 4.67% C6H8O7.

Let's say we want to add 2% of our oil weight in C6H8O7 and all we have is a bag of lemons. What should we do? Let L be the amount of lemon juice we need to obtain our C6H8O7, and assume our total fat weight is 1,000g.

Then (L)(.0487) = 20g, and L = 410.68g lemon juice. Yikes - that's a lot!

A quick google search will tell us that about 92.3% of this 410.68g is water.

We would probably consider a (410.68)(.923) = 379.06g water discount.

And we would need to add (20)(.624) = 12.48g NaOH to our recipe.

That lemon juice word problem was the smoothest transition between chapters to date.

CHAPTER 8: THE PRETTY THINGS

MILKS, JUICES, & PUREES, EXFOLIANTS & FRAGRANCES, LAYERING & SWIRLING

There isn't a great reason to use milks, juices, or purées in soaps, I don't think, except that it's a fun thing to do. It's important to understand that the pH transformation that happens in soaping does not allow for mold and bacteria to grow, assuming that all of the soap batter saponifies. However, soap is still subject to oxidation, and ingredients can brown. Browned soaps are still perfectly safe to use, as are soaps with DOS (rancid unsaturated fatty acids) soda ash (NaOH and CO2), glycerin rivers (high temps/too much water), or stearic spots (solidifying saturated fatty acids).

Additives can be incorporated at any time: as part of the NaOH solution, as part of the fats, or blended into the emulsion (thin trace). Pureés are often added to oils or at thin trace, and liquids are often used in place of water in the NaOH solution. To prevent the scorching of ingredients, liquids can be frozen into cubes before sprinkling NaOH onto them. As we discussed earlier, liquids can also be added later when using a concentrated master-batched aqueous NaOH.

We can break down our additives by water content, sugar/alcohol content, and in the very extreme circumstance we created last chapter, acid. Mostly, pureés are used in very small percentages - up to 6%, or about one ounce (28g) per lb (454g) of fats.

Sugar and alcohol both boost lather, increase temperature, and accelerate trace, thereby putting soaps at higher risk of volcanoing. Soap molecules have hydrophobic and hydrophilic parts, but so do sugars and alcohols. Soap molecules have long hydrophobic parts with short hydrophilic parts, so they're more fatty than watery. Sugars and alcohols, on the other hand, have long hydrophilic parts with shorter hydrophobic parts, so they're more watery than fatty. Their molecules can cluster around the hydrophilic parts of the soap molecules, making them more attractive to water molecules, which results in a quicker emulsification. Let's move on, because as a chemistry hater, I already stopped paying attention to my own writing like two sentences ago.

It can be scary using accelerating ingredients, but remember - we can do a lot to control the temperature. Before emulsification, we have room temperature and time. To cool ingredients or solutions, we have ice baths, ice packs, freezers, and refrigerators at our disposal. To warm ingredients or solutions, we have saponification which can be induced through agitation, electric blankets, and ovens. Either way, we can also use towels as insulators.

Honey, a very popular additive, is 80% sugar. Sugar is of course 100% sugar, but it is often made into a simple syrup for soaping.

Beers and wines are typically boiled down and cooled to eliminate some of the alcohol and all of the carbonation. It is recommended to use no more than 5%, or about 23g of sugar or alcohol per lb (454g) of fats. That's just under 5 teaspoons of sugar. A 4 oz pour of wine at 12% alcohol or a 12 oz beer at 5% alcohol yield 14 grams of alcohol, and after boiling for 15 minutes, less than 6g. After boiling longer, less than that. So one typical drink falls within a safe realm for soaping even before boiling.

Let's talk about milk, which is 87% H2O. Milk scorches very easily, so it needs to be handled carefully. In fact, it scorches at 83°C, which can happen during gel phase, so it's necessary to prevent gel phase in milk soaps by placing the molds into the freezer for 24 hours immediately after pouring. Milk soaping temperatures are typically around 24-27°C.

If wanting to maximize the amount of milk, frozen cubes of milk would be used to create the NaOH solution. When creating an aqueous NaOH, it's easy to see when the NaOH has fully dissolved because the solution will be clear. With milks, teas, coffees, or juices, that can be more difficult, but once the temperature of the solution starts to descend, the NaOH has been fully dissolved. Milk and lye solutions always have a terrible smell, but that smell dissipates after a week or so.

Yogurt is treated more like a purée and normally added to trace at TPPO.

Exfoliants that bleed color like coffee grounds, tea, and herbs can be made into disgusting poisonous teas, steeping from the heat of the dissolving NaOH. Adding them later runs the risk of color rings. Exfoliants like ground shells, spices, seeds, grains, flower petals, or dried citrus can simply be added to the oils or sprinkled on the top of the soap after pouring. Powdered foods are used more like mica powders or powdered clay.

When it comes to adding fragrances, there are two main choices: essential oils and fragrance oils. In both cases, different fragrances can greatly accelerate trace, and roughly 2-5% weight of fats are used. The fragrance oils of the soaping world are like the LorAnn flavor oils of the baking world - they're specially formulated for this particular craft; some are even formulated to perform well specifically in cold process soaping. You can't just throw any ingredient into a chemical reaction and expect nothing to happen, which is why essential oils can have more unpredictable results or lose their scents more readily than fragrance oils.

If I had to make my first batch of soap tomorrow and sell it to the public, I would use fragrance oils. They are built to endure the harsh process that is soaping, and come with information specific to soaping. Still, there is something unnerving to me about clear bottles of liquids labeled "golden oats, milk, and honey" or "gingerbread" or "cashmere." If I were making soap for friends and family only, I might try unscented soap or throw caution to the wind and use essential oils.

Amongst the throwing of cautions, one might also remember that some essential oils can cause skin irritation. I once made an orange cinnamon bath bomb for my mom, which was worse than it sounds. To see the maximum recommended amount of any essential oil, you can consult the official document from the International Fragrance Association: The Complete IFRA Standards.

When concerning ourselves with the soap making process only, and not how terrible our soaps may feel, it is important to remember that some oils will rapidly accelerate trace. Cinnamon, clove, and many floral scents, which tend to be alcohol based, are the biggest culprits.

When working with essential oils in soaping, popular choices include:

For essential oils to remain fragrant or "stick," it is recommended to make a blend containing "top notes," "mid notes," and "base notes." Examples of top notes, which fade most quickly, are citrus and mints. Some mid notes are lavender, lemongrass, rosemary, and tea tree. Some base notes are cedar, patchouli, and ylang ylang.

That's really all I wanted to say about fragrances, but before we move onto the looks, there's a special additive that deserves a mention all on its own. Rosemary oleoresin extract is an antioxidant that prevents the oxidation of fats in soap, which means they're less likely to go brown and rancid and create DOS. It's used at .05% total weight of fats.

The reason people usually fall in love with soap isn't the antioxidants or even the cashmere fragrance oil - it's the swirls. Layering is easy enough - you black and tan your way with a medium trace.

Swirling requires a thin to medium trace; the thicker the trace, the more distinct colors will be and the thicker the swirling tool must be. There are all sorts of ways to pour and all sorts of ways to swirl. If you can imagine it, you can do it.

In the baking world, wet on wet royal icing techniques pretty much cover the world of swirling in two dimensions, and the very top layer of a soap loaf is usually handled just like a sugar cookie. But underneath, getting a swirl for the cross cut is a different matter altogether. Some ideas work better with vertical cuts (hanger swirl), and some are specifically designed for horizontal cuts (Taiwan swirl). I'll cover a handful of general ideas.

Swirls can be created from pouring alone. The most basic technique, the "in-the-pot swirl" requires swirling differently colored soap batters in the pouring vessel before the pour. This results in irregular thinly layered looking swirls, like what you might see when you cut a rock open. A fancier variation of this same idea, the "dustpan swirl," involves pouring the soap batter in layers into a dustpan (just like a zebra cake) and then using the dustpan as the pouring vessel.

If we're not swirling "in the pot," we could swirl with the pour itself. When a device is placed onto a slab mold to help guide the pour into a pattern, this is called a "column pour." The "drop swirl" consists of pouring differently colored soap batters in swirled or zig-zag motions. This results in big fun blotchy swirls, like what you might see in a lava lamp. Here are some excellent swirls that use these ideas.

The most common technique is to pour your soap in horizontal layers (medium trace) and use a "hanger tool" to create swirls. Layers are poured from bottom to top in rectangular prism molds, so the appropriate swirling tool must influence layers from bottom to top and run the entire length of the mold. Imagine the bottom of an alkaline-proof wire hanger.

A gear tie works nicely for this, and many soap hangers for purchase are essentially gear ties. This is the most practical hanger tool because the gear tie can be reshaped to fit any mold. Gear ties won't readily conform to perfectly straight lines, and for the purposes of swirling, that doesn't really matter at all. For the perfectionists, however, there are also perfectly straight rigid hangers for sale, but these have to be custom ordered to fit the length of the molds in mind. Hanger swirls are very practical; they're effective, easy to visualize, and designed for vertical cutting.

Two other popular swirling tools are chopsticks and spoons. Chopsticks or rods can be used to swirl downwards at a 45° angle to create vertical cut swirls.

On the other hand, dividers for soap molds can be purchased to create vertical layers, just like checkerboard caking. The dividers are removed and the rods can be used straight up and down, essentially going back to 2 dimensional wet on wet royal icing techniques, in which the patterns remain fairly similar from the top to the bottom of the loaf. These designs are called Taiwan swirls, and can either be cut horizontally or poured in a slab mold, in which the cuts form the edges - not the sides - of each bar of soap.

Spoon swirling yields less predictable results, and the spoon handle is slowly twirled as the spoon mixes the bottom soap layers into the top. Here are some examples.

I almost didn't want to write about the kaleidoscope swirl because it's so specific, but in the interest of being more thorough, I'll give you a couple sentences. This is like when I covered Russian piping tips in my piping tip post. There's a cylindrical mold you can buy that's designed to stand upright. Layers are poured to fill the length of the cylinder, and then a metal plate is pulled upwards through the layers.

There are many more soap decorating techniques, but I'm not trying to write a book on it. Some soapers create entire landscapes or pictures in their vertical cuts, often with the help of pre-cut soap scrapers. (The soap batter has to be at the right thickness for that to work). Similarly, smaller silicone molds can be used to create shaped columns to suspend in soap batter. When adhering several layers together, rubbing alcohol is often sprayed to help strengthen these joints. Sometimes, soap is cut while still flexible and reshaped into veneers for other soaps. Smaller molded soaps or piped soap batters can also be applied for finishing touches. But that's not really what George Todd is about, so let's fast forward.

CHAPTER 9: GEORGE TODD THE SOAP MAKER

AND HIS 47-PIECE SOAP MAKING KIT

I never meant to write this post. I went online and searched "deluxe soap making kit," and what I had expected was a pamphlet that was more or less a printout of this post, along with some sturdy reusable supplies of reasonable quality. That's what I did with the beer making kit, and it worked out very nicely. But does that exist in the soap making world? It does not. So I had to create my own, and this is the end of the pamphlet it came with. Happy 47th, Jabber.

And in case you want to make your ice cream cake before we play with poison, here's your

PECAN PRALINES ICE CREAM CAKE

CHAPTER 10: OUR VERY FIRST RECIPE

LET'S USE YOUR KIT

A word on tar. Tar is a dark, thick, sticky liquid made of hydrocarbons and free carbon obtained from coal, wood, petroleum, or peat by heating it under conditions that limit the amount of oxygen - a process called destructive distillation. When pine wood goes through destructive distillation, charcoal and pine tar are produced. Pine tar has been used in woodworking as a preservative and sealant, in baseball to increase grip, and in soap to treat skin diseases such as psoriasis, eczema, and rosacea.

Although pine tar has no fatty acids, it does have a saponification value of .043, and is usually used at 5-20% of the weight of the fats, with about 10% being a popular choice. Pine tar soap batter has a very fast trace, so it is normally hand mixed without the help of an immersion blender.

I looked up a few pine tar recipes, and settled on basing ours off of this one by The Nerdy Farm Wife. I also followed her recommendations for which pine tar, soap mold, and lye to work with.

My personal soaping philosophy is that there is nothing particularly magical about transforming lovely vegan oils into lovely vegan soaps.

I was eyeballing that two cups of rendered turkey fat this year in a way I never had before. Animal fats can be bought from a butcher, but we should also ask HEB if they have beef fat we could render into tallow; I cannot imagine it would be too expensive. All animal fats need to be rendered, strained, and of course cleaned if they're gross. And yes, people make (and like) bacon grease soap. We'd save a lot of time from several rounds of washing rendered fats, which is a matter of boiling fat and letting the gross stuff come out into the water, if we strain it through a coffee filter before storing it in the first place, probably into a jar, and probably kept in the freezer. Mrs. Lovett is eminently practical and yet appropriate as always.

Because you prefer high cleansing soaps made with saturated fatty acids, and I like reusing animal products that would normally be wasted instead of deforesting the planet our children must one day endure without the shields of our parental protection, I think we should adjust The Nerdy Farm Wife's recipe to include lard. Tallow is more traditionally used for soap making, but our grocery stores don't carry it. Lard is 46% oleic, 28% palmitic, and 13% stearic, so maybe something like this would work.

Lye Calc says that makes a pretty good soap, actually, and its only weakness is a low ranking on longevity, which is an aspect of pine tar soaps in general. Anyway, we don't have to do exactly that; we can play with it.

This is the process:

There hasn't really been a very good place to elaborate on curing, so we'll do it now. Every bar of soap is made of solid/crystal and liquid parts. The most common soap molecules are lauric, myristic, palmitic, stearic, and oleic. The first four are made with saturated fatty acids, ordered by size. The bigger sizes are more insoluble, so stearic soap is barely soluble and palmitic soap is moderately soluble. These are the bubbly soaps. Oleic acid, as you probably recall, is a monosaturated fatty acid, which makes the resulting molecule a big bulky shape, and that makes it less likely to fit into the crystal parts.

Once the excess water in the soap has evaporated, stearic and palmitic soaps start to transform from the liquid parts of the soap to the crystal parts! Lauric, myristic, and oleic soaps remain in the liquid parts. As the crystal parts of the soap become filled with a higher percentage of stearic and palmitic soaps, they become less soluble, and the bar of soap lathers better.

EPILOGUE

ACKNOWLEDGEMENTS & SOURCES

SOURCES

This is not a complete list of sources, but I've included those I found most helpful.